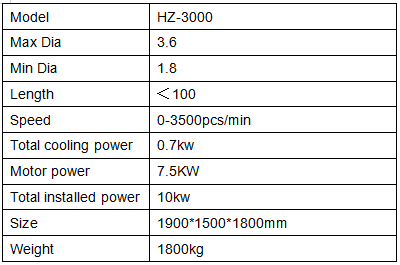

Model : HZ-3000

Max Dia : 3.6

Min Dia : 1.8

Length : < 100

Speed : 0-3500pcs/Min

Total cooling power : 0.7Kw

Motor Power : 7.5Kw

Total installed power : 10Kw

Size : 1900*1500*1800mm

Weight : 1800kg

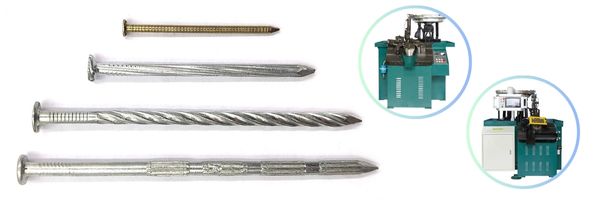

Unlock the next level of efficiency and precision in your manufacturing process with our advanced automatic thread rolling machine. Engineered to deliver superior performance, this machine is the ideal solution for processing various diameters, lengths of straight rod threads, and an array of special-shaped nails.

Our thread rolling machine for sale has below key features:

Electromagnetic Vibration Feeding System: Equipped with an automatic control feeding facility, ensuring a smooth and consistent material supply.

Synchronized Feeding Mechanism: The machine incorporates a synchronized feeding system, allowing for precision and efficiency in the threading process.

Variable Frequency Drive (VFD) Control: The main motor is controlled by a frequency converter, making it easy to adjust the machine's speed and productivity as per your production needs.

Clean Working Environment: This machine is designed to operate in a clean environment, producing nails that are bright, clean, and of the highest quality.

Structure & Working Principle:

The thread rolling machine is composed of our primary systems:

1.Vibration Feeding System: Handles the organized and automatic arrangement of nails, guiding them into the feeding mechanism.

2.Thread Rolling Forming System: Performs the precise rolling and extrusion of threads, shaping the nails into the desired specifications.

3.Main Transmission System: Powers the machine's operations, ensuring smooth and reliable performance.

4.Electrical Control System: Provides comprehensive control over the machine's functions, allowing for easy operation and adjustments.

Production Process:

The process begins by placing the nails into the vibration disc. The vibrating disc then arranges the scattered nails in sequence, guiding them through the feeding track into the nail feeding mechanism. This mechanism feeds the nails into the rolling die, where they are rolled and extruded into the desired shape and size. The entire process is fully automated, requiring only the initial placement of nails into the vibration disc.

High Precision & Durability:

Our Thread Rolling Machine is equipped with high-precision, long-life linear guide rails, ensuring accurate and consistent feeding. This feature not only enhances the machine's longevity but also guarantees the production of top-quality nails every time.